Sale Tel

+86 18237175581

Sale Tel

+86 18237175581

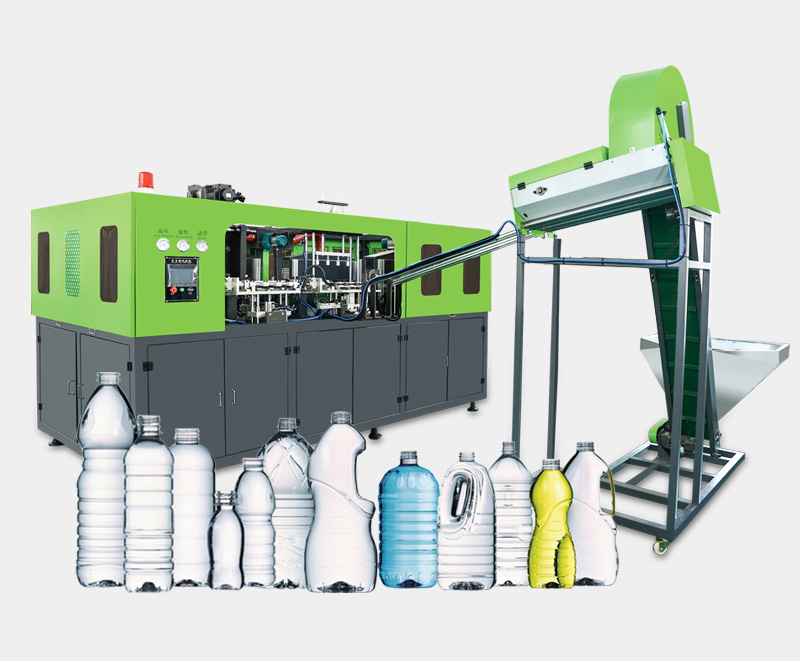

Are you curious about how the beverage bottles, mineral water bottles, milk bottles, medicine bottles, cooking oil barrels, etc. that we drink in our daily life were born? In fact, this is due to the "blowing" of the bottle blowing machine, which uses the blow molding process to make plastic particles into hollow containers, which produces all kinds of bottles we need.

Blow Molding Machine, as the name suggests, it refers to the mechanical equipment for blowing bottles. Simply put, it refers to a machine that can blow plastic particles (softened into liquid) or preforms into bottles of various shapes and sizes through certain technological means. The bottle blowing machine is convenient and quick and has a large molding capacity. Since its inception, it has gradually replaced most manual bottle blowing and has been adopted by most food and drinking water companies.

A semi-automatic PET bottle-blowing machine is the most cost-effective solution for the mass production of jars and bottles for small and medium-scale factories. The PET bottle-making machine is also designed for the production of big jars and containers.

Two-stage semi-automatic PET blow molding machine is fit to blow carbonated beverage bottles, mineral water bottles, cosmetics bottles, and hot-filling bottles. A microcomputer controlling system, it controls various technical parameters needed more accurately and more steadily. It can operate easily without any special training and more safely.

Automatic PET stretch blow molding machine is a new generation of automatic PET bottle manufacturing machine for mass production of PET bottles and jars, Ideally suitable for medium and large scale factories and for applications where stringent quality requirements have to be met. Substantial reduction in operating cost is achieved by saving manpower.

We offer 4-cavity automatic PET stretch blow molding machines, 6-cavity automatic PET bottle blowing machines, and 8-cavity PET stretch blow molding machines. They can blow bottles in shapes such as carbonated, mineral, pesticide, cosmetics, wide-mouth, hot filling, and other packing containers, which are made of plastic of crystalline type such as PET and PP, etc.

| Plastic bottle-blowing machine | YG-2L-2 | YG-2L-4 | YG-2L-6 | YG-2L-8 |

| Cavity | 2 | 4 | 6 | 8 |

| Theory output | 2000-2700 | 4000-5000 | 6000-7200 | 8500-9000 |

| Max. volume | 2L | 2L | 2L | 2L |

| Bottle mouth maximum overall diameter | 80mm | 28-38mm | 28-38mm | 28-38mm |

| Bottle biggest diameter | 100mm | 100mm | 100mm | 100mm |

| Bottle maximum height | 330mm | 330mm | 330mm | 330mm |

| Light tube quantity | 16pcs | 40pcs | 64pcs | 32pcs |

| Low-pressure gas consumption | 1000L/min | 1600L/min | 1600L/min | 1600L/min |

| Blow bottle pressure | 25-35kg/c㎡ | 25-35kg/c㎡ | 25-35kg/c㎡ | 25-35kg/c㎡ |

| Temperature range | 10℃ | 10℃ | 10℃ | 10℃ |

| Consumption | 5000kcal/hr | 8000kcal/hr | 8000kcal/hr | 12000kcal/hr |

| Frozen water flow | 30L/min | 88L/min | 88L/min | 88L/min |

YG Machinery's blow molding machine is suitable for blowing plastic containers and plastic bottles of any shape and various sizes and capacities made of PET, PP, and PC. It is widely used in blowing carbonated beverage bottles, mineral water bottles, baby bottles, oil bottles, petroleum bottles, cosmetic bottles, pesticide bottles, medical bottles, space cups, and lampshades, etc.

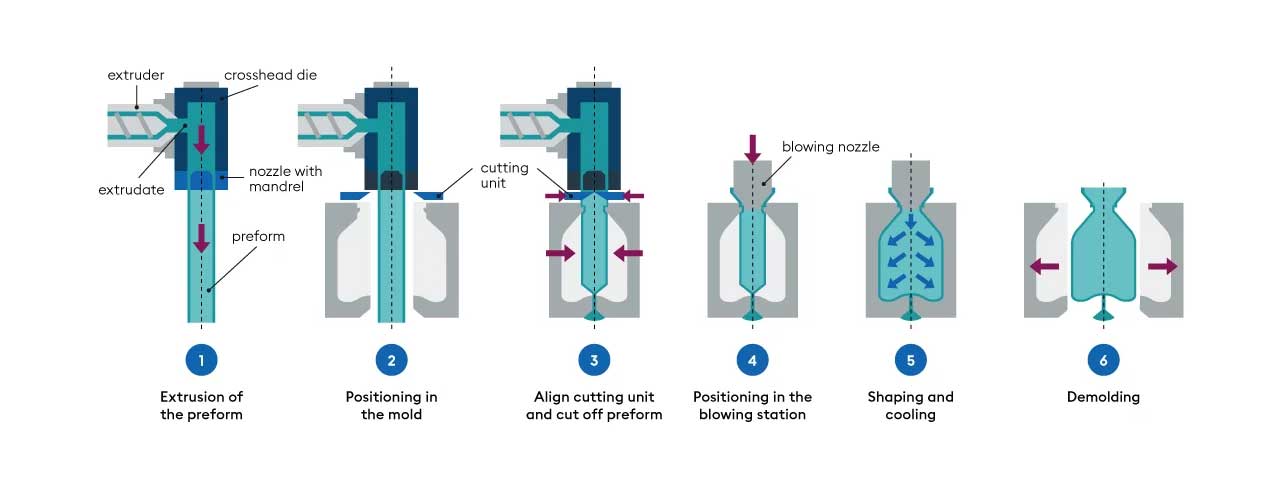

The blowing process of the blow molding machine is divided into two parts:

The preform (embryo) is irradiated by an infrared high-temperature lamp to heat and soften the bad part of the preform (embryo). In order to maintain the shape of the bottle mouth, the mouth of the preform (embryo) does not need to be heated, so a certain cooling device performs the cooling operation on it.

In this stage, the preheated preform (embryo) is placed into the blow mold that has been prepared, and the inside is inflated with high pressure. Blow and stretch the preform (embryo) into the required bottle. The semi-automatic bottle blowing machine needs to manually put the preheated preform into the blow molding position, which requires extra labor and is inefficient.

The automatic bottle blowing machine combines the two operations of the blow molding machine through the operation of the manipulator, eliminating the need to put the preheated preform into the blow mold manually. Greatly accelerated the rate of production

The quality of the bottle blowing equipment determines the final molding effect of the plastic bottle, especially the angle of sealing is very important. Therefore, it is particularly important to choose a bottle blowing machine with good quality and high performance. YG Machinery will provide professional bottle blowing machine solution according to your need.

InquiryPlease feel free to submit your inquiry to us. We will contact with you as soon as possible

)