Sale Tel

+86 18237175581

Sale Tel

+86 18237175581

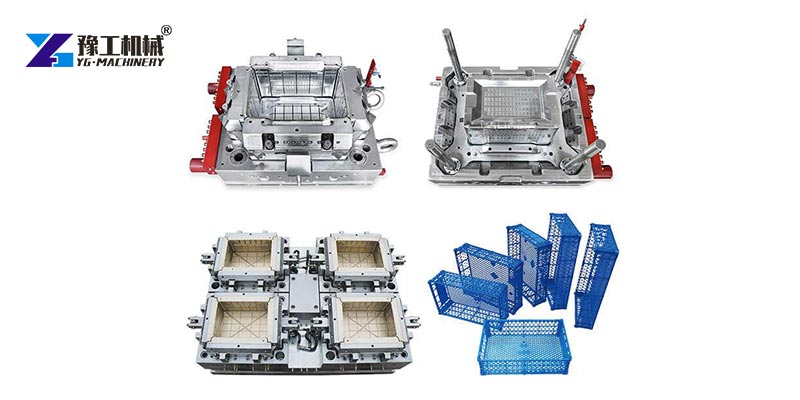

With the needs of global development, the demand for plastic turnover boxes in all walks of life is increasing. Plastic turnover basket injection molding machine is also gradually emerging in the plastic products industry. The turnover basket is made of brand-new PP material, which is safe and environmentally friendly. The centralized feeding system is used for unified injection molding, automatic manipulator grabbing, and assembly line production. The product has the characteristics of lightweight, heavy load, space-saving, durability, safety, environmental protection, etc., which meet the standardization requirements. The important thing is that it can be equipped with smart devices such as label chips, realize information management, and support color and size customization.

Plastic turnover box production machines usually refer to plastic turnover box injection molding machines. It is also called turnover box injection making machine. It is the quintessence of the injection industry, a standard model developed by itself after digestion and absorption combined with market demand. Plastic turnover box injection molding machine has the advantages of simple operation, high work efficiency, low noise, and low energy consumption. It is suitable for the production of various types of plastic turnover boxes, crystal tableware, and other plastic products. As a type of industrial injection molding machine, plastic turnover box injection molding machines are widely used in industry, electronics, automobiles, civil and other industries.

With the widespread application of plastic turnover boxes, the demand for plastic turnover basket injection molding machine is also growing. Nowadays, plastic turnover boxes of various types, specifications, and uses have been produced. It is widely used in textiles, clothing, aquaculture, electronic products, pharmaceuticals, engineering parts, processed food, fishery, dairy products, breweries and bottling plants, poultry, agriculture, refrigeration, fruit and vegetable processing, and beverage, and automotive industries. Therefore, it can be seen that Plastic Turnover Box Injection Molding Machine has a wide range of uses.

Raw materials suitable for this plastic turnover box making making can be waste plastic, PP, PE, PVC and so on. The plastic turnover box can be used for packing and also for stock storage as bearers, and it is environmental friendly. The plastic turnover basket making machine is the very good equipment for plastic recycling.

| Item | Model | TH520/FS | TH520/SP | TH460/SP | TH400/SP | TH360/SP |

| Injection Unit | Screw diameter(mm) | 100 | 95.0 | 90 | 80.0 | 75.0 |

| Screw L/D ratio(L/D) | 20 | 18.8 | 18.3 | 19.7 | 18.6 | |

| Theroy Injection Volume(cm3) | 3173.0 | 2863.6 | 2512.9 | 1759.3 | 1305.4 | |

| Injection weight(g) | 3395.1 | 3064.1 | 2688.8 | 1601.0 | 1206.1 | |

| Injection pressure(MPa) | 121.8 | 135.0 | 128.3 | 156.4 | 155.6 | |

| Injection rate into air(cm3/s) | 766.3 | 622.4 | 681.8 | 512.8 | 515.6 | |

| Injection stroke(mm) | 404 | 404 | 394 | 350 | 300 | |

| Injection speed(mm/s) | 97.6 | 87.8 | 104 | 102 | 116.7 | |

| Maximum speed of screw(rpm) | 157.3 | 141.6 | 182.0 | 166.9 | 211.5 |

The adoption of worldwide advanced and well-known servo systems can reduce energy and water consumption by as much as 80%.

Low (rotation speed) inertia motor possesses up to three times more instantaneous overload capacity than the common motor and reaches the highest speed of 2500r/m. It can satisfy the customers better for their requirements of products with fast response.

Turnover basket series equipment adopts double alloy screw barrel screw, corrosion resistance, and wear resistance, greatly prolonging the service life of the machine.

The repeatability can reach 0.5% even if the machine is running at extremely low speed and long holding pressure.

There is mechanical, hydraulic, and electrical triple protection. The independent control of the safety module will ensure the correct operation of all parts of the machine and avoid any accidents.

The machine can be equipped with a manipulator or ejector cylinder so that the safety door products can be taken out without manual hand pulling.

YG Machinery specialized in making PET preforms, caps, pails, buckets, jars, covers, and lids. Special screw for PET products, all machines adapt latest control system, hydraulic valve for highest quality standard and machine performance. YG Machinery's injection molding machine all processes and elements are perfectly coordinated. You can rely on the best part quality, stable processes, and high productivity. We are also able to provide mold designing and manufacturing to help you build up all kinds of plastic items manufacturing. YG Machinery as a professional injection molding machine manufacturer, we have the most advanced technology and the most abundant experience. And we have a source factory that covers a huge area. We can definitely provide the most thoughtful service to all users. If you are interested in various types of injection molding machines, please feel free to contact us.

InquiryPlease feel free to submit your inquiry to us. We will contact with you as soon as possible

)